Holding Tank maintenance - winter 2011

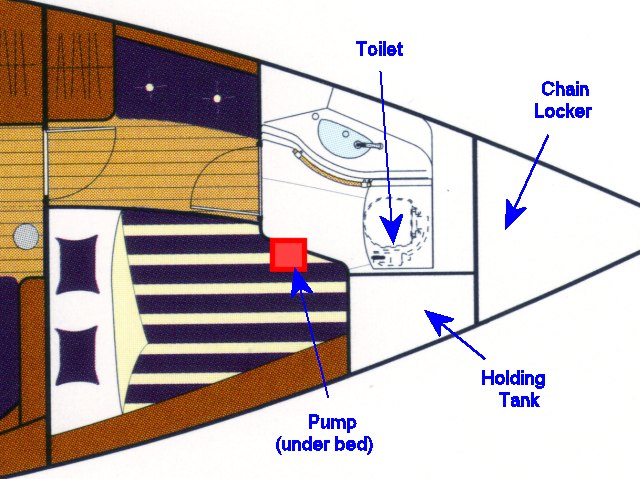

>Forward cabin layout

Waste products that should not be discharged in coastal waters (especially at anchor in cala's) so they are diverted to holding tanks until they can be discharged at sea. Typically there are two types, black water (toilet output) and grey water (sink discharge). Most Mediterranean countries prohibit the discharge of black water in coastal areas and a few (very few) also prohibit the discharge of grey water – notably some parts of Greece who will be assured of clean seas devoid of all but local boats who don't appear to be subject to the excessive fines!

>Forward cabin layout

Waste products that should not be discharged in coastal waters (especially at anchor in cala's) so they are diverted to holding tanks until they can be discharged at sea. Typically there are two types, black water (toilet output) and grey water (sink discharge). Most Mediterranean countries prohibit the discharge of black water in coastal areas and a few (very few) also prohibit the discharge of grey water – notably some parts of Greece who will be assured of clean seas devoid of all but local boats who don't appear to be subject to the excessive fines!

Our boat was commissioned in the UK where black water holding tanks are not a requirement but I had them factory fitted as an optional extra. The best quality flexible 38mm pipe used in boats has a guaranteed life of 5 years. That's very short compared to waste plumbing in a house. This year we had problems with both the forward and aft holding tanks. The tanks themselves are in good condition but the hoses, pumps and connections were causing odorous problems. The factory design for emptying the tanks at sea is by manual bilge pump operated from inside each head (toilet).

Forward head.

Due to the layout of the boat one of the walls of the forward toilet abuts the forward cabin, therefore the through-bulkhead manual pump is actually located under the bed in that cabin and operated from inside the toilet. This required two 38mm pipes connected to the pump which due to routing difficulties and time have developed pin-hole leaks.

The forward holding tank is located almost directly over the through-hull outlet so I simplified the design to a direct gravity discharge controlled by an expensive manually operated plastic valve thus eliminating two pipes and a manual pump. In practice it took several attempts to get a completely watertight (excrement-tight) seal – I tested with sea-water! The main problem was that the pipe from the through hull fitting didn't line up exactly with the fitting into the bottom of the tank causing stress on that joint. The final solution was to coat the whole joint with Sikaflex 291 sealant before screwing them together. After several trials I re-installed the covers. One down, one to go.

The forward holding tank is located almost directly over the through-hull outlet so I simplified the design to a direct gravity discharge controlled by an expensive manually operated plastic valve thus eliminating two pipes and a manual pump. In practice it took several attempts to get a completely watertight (excrement-tight) seal – I tested with sea-water! The main problem was that the pipe from the through hull fitting didn't line up exactly with the fitting into the bottom of the tank causing stress on that joint. The final solution was to coat the whole joint with Sikaflex 291 sealant before screwing them together. After several trials I re-installed the covers. One down, one to go.

Aft head.

The aft tank was a different problem. The through-hull discharge is quite a distance from the tank so the pump is essential, however the hot-air central heating pipe passes through the space under the holding tank where the pump is located. The hot-air pipe had developed a leak near the discharge pump and melted the pump clamp ring causing a leak. Also, because the flexible discharge pipe from the tank has to go under the heating pipe it creates a sump reducing the life of the pipe and there were several pinhole leaks. I decided to solve the problem by using conventional PVC rigid pipe as used in housing to link the tank and pump passing under the heating pipe with three 90 degree elbows and various lengths of pipe. Ambitious because working space is very limited.

The new design - but it leaked

Alignment to the bottom of the holding tank and discharge pump through the rigid pipe and three elbows was very difficult and had to be precise because of the short distances involved. It required measuring, cutting, fitting and trimming a centimetre at a time until it was correct. Then when it was all in place I marked each joint with a felt-tip pen to get the angle of alignment correct. The heart stopping phase was gluing them together – the point of no return! It worked, after gluing they were still aligned.

The new design - but it leaked

Alignment to the bottom of the holding tank and discharge pump through the rigid pipe and three elbows was very difficult and had to be precise because of the short distances involved. It required measuring, cutting, fitting and trimming a centimetre at a time until it was correct. Then when it was all in place I marked each joint with a felt-tip pen to get the angle of alignment correct. The heart stopping phase was gluing them together – the point of no return! It worked, after gluing they were still aligned.

Meanwhile, I ordered and received a maintenance kit for the Whale Gusher Titan Bilge Pump (the discharge pump) and re-furbished it before re-installing the tank. The maintenance kit was priced at 72 Euro here so I ordered it on-line in the UK for just over £28 and Glyn and Emma kindly forwarded it.

After servicing the discharge pump I installed the holding tank, connected everything up and tested it (with fresh water!). All seemed to be well but after several hours the paper towel I had strategically placed was damp. There was seepage which I finally traced to one of the glued joints. At this juncture I bought some more flexible tube and installed it to the original design although the implementation was akin to wresting with a fully grown anaconda but it worked.

Top